CNC-Bearbeitung Online

- Expressfertigung ab 7 Tagen

- CNC-Teile Online bestellen

- Aluminium, Stahl, Kupfer, Polymere

- Prototypen- und Serienfertigung

- Zertifizierungen und Prüfberichte

Ein neues CNC-Angebot anfordern

STEP | STP | SLDPRT | STL | IPT | 3DXML | CATPART | PTC | PRT | SAT

CNC-Bearbeitung Online: Kalkulieren und Bestellen

Bestellen Sie Ihre CNC-Teile jetzt und lassen Sie sie in bis zu 10 Tagen fertigen

Xometry ist ein führender Online-Fertiger, der Ihnen die CNC-Bearbeitung von Bauteilen jeglicher Komplexität für Klein- und Großserien anbietet. Mit unserem innovativen Instant-Quoting-System erhalten Sie innerhalb von Sekunden ein Angebot für die CNC-Fertigung Ihrer Metall- oder Kunststoffteile. Nach der Bestätigung Ihres Angebots fertigen wir Ihre Teile schnell und zuverlässig. Innerhalb von nur 10 Tagen liefern wir Ihre fertigen Bauteile direkt zu Ihnen.

Unser Team von Experten überprüft jedes Teil sorgfältig, um sicherzustellen, dass es den höchsten Qualitätsstandards entspricht. Darüber hinaus bieten wir auf Anfrage verschiedene Nachbearbeitungen für Ihre CNC-Bauteile an, wie z.B. Beschichtungen, Hitzebehandlungen und andere Verfahren, um sicherzustellen, dass Ihre Bauteile perfekt auf Ihre Anforderungen abgestimmt sind.

Xometry kann auf Wunsch auch Zertifizierungen (Konformitätszertifikat, Rohstoffzertifikat, etc.) und Prüfberichte (CMM, FAIR, Messbericht) erstellen.

Lernen Sie, wie Xometry funktioniert

Testen Sie Xometry jetzt in nur wenigen Schritten

Laden Sie zunächst Ihre CAD-Datei hoch. Sie können gleichzeitig mehrere Designs für verschiedene Frästeile online importieren, um ein einziges Angebot zu erstellen. Innerhalb weniger als einer Minute erhalten Sie einen detaillierten Kostenvoranschlag auf Ihrem Bildschirm.

Wählen Sie das gewünschte CNC-Bearbeitungsverfahren und treffen Sie eine Auswahl aus einer Vielzahl von Materialien, einschließlich Metallen und Kunststoffen, sowie einer breiten Palette von Veredelungen und Zertifizierungen, um die perfekte Kombination für Ihre Anforderungen auszuwählen.

Sobald Sie die gewünschten Optionen ausgewählt haben, bestätigen Sie einfach Ihre Bestellung und zahlen direkt über unsere sichere Zahlungsplattform. Profitieren Sie von unserem Know-how, da Ihr Entwurf von unseren Ingenieuren sorgfältig analysiert wird.

Unser Express-Service stellt sicher, dass Ihre Teile innerhalb kürzester Zeit direkt an die von Ihnen gewählte Lieferadresse gesendet werden. Sie können Ihr Paket jederzeit online in Ihrem persönlichen Xometry-Konto unter „Meine Bestellungen“ verfolgen.

Entdecken Sie die Vorteile der CNC-Bearbeitung bei Xometry

Schnelle Abwicklung

Als führender Online-Fertiger nutzt Xometry die neuesten CNC-Maschinen, um hochpräzise CNC-Teile in nur 10 Tagen zu produzieren.

Präzision

Xometry bietet verschiedene Toleranzoptionen nach ISO 2768 (Standard, Fein) und ISO 286 (Grade 8, 7, 6) für maximale Präzision bei der Fertigung Ihrer Teile.

Kundenspezifische Oberflächen

Wählen Sie aus einer Vielzahl von Oberflächenbehandlungen für Metall- und Kunststoffteile, die nach präzisen Designspezifikationen gefertigt werden.

Materialauswahl

Wir bieten über 40 verschiedene Materialien aus Metall und Kunststoff an, die nach höchsten Standards zertifiziert sind. Die CNC-Bearbeitung bietet eine große Auswahl an zertifizierten Materialien.

Qualitätssicherung

Unsere QA-Abteilung führt eine umfassende Qualitätssicherung durch, um sicherzustellen, dass Ihre Teile perfekt gefertigt werden.

Zertifizierungen und Prüfberichte

Xometry kann Zertifizierungen (Konformitätszertifikate für die Auftragsarten 2.1 und 2.2, Rohstoffzertifikate für Metalle und Kunststoffe, Wärmebehandlungsprotokolle und RoHS-Zertifikate) und Prüfberichte (CMM, First Article Inspection Report – FAIR, Messbericht) zur Verfügung stellen.

Bestellen Sie Ihre CNC-Teile jetzt und lassen Sie sie in bis zu 10 Tagen fertigen

Zum Sofort-AngebotAlle Uploads sind sicher und vertraulich.

CNC-Bearbeitungsmaterialien

- Aluminium 2007 / 3.1645 / Al-CuMgPb

- Aluminium 2017A / 3.1325 / Al-Cu4Mg

- Aluminium 6060 / 3.3206 / Al-MgSi

- Aluminium 6061 / 3.3211 / Al-Mg1SiCu

- Aluminium 6082 / 3.2315 / Al-Si1Mg

- Aluminium 7075 / 3.4365 / Al-Zn6MgCu

- Stahl 1.0038 / S235JR

- Stahl 1.0503 / C45

- Stahl 1.0511 / C40

- Stahl 1.0570 / S355J2G3

- Stahl 1.2842 / 90MnCrV8

- Stahl 1.7131 / 16MnCr5

- Stahl 1.7218 / 25CrMo4

- Stahl 1.7225 / 42CrMo4

- Edelstahl 303 / 1.4305 / X10CrNiS18-9

- Edelstahl 304 / 1.4301 / X5CrNi18.10

- Edelstahl 304L / 1.4307 / X2CrNi18-9

- Edelstahl 316 / 1.4401 / X5CrNiMo17122

- Edelstahl 316L / 1.4404 / X2CrNiMo17-12-2

- Edelstahl 316Ti / 1.4571 / X6CrNiMoTi17-12-2

- Kupfer E-Cu57 / E-Cu58 / Cu-ETP / 2.0060 / 2.0065

- Messing Ms58 / 2.0401 / CuZn39Pb3

- Titan Grad 2 / 3.7035

- Titan Grad 5 / 3.7164 / 3.7165 / Ti-6Al-4V

- ABS

- Acryl

- Industrielle PEEK

- Nylon 6

- PC (Polycarbonat)

- PEEK glasfaserverstärkt

- Polypropylen (PP)

- POM / Delrin Acetal

- PTFE / Teflon

- PVDF / Polyvinylidenflourid

- UHMW PE / Ultrahochmolekulares Polyethylen

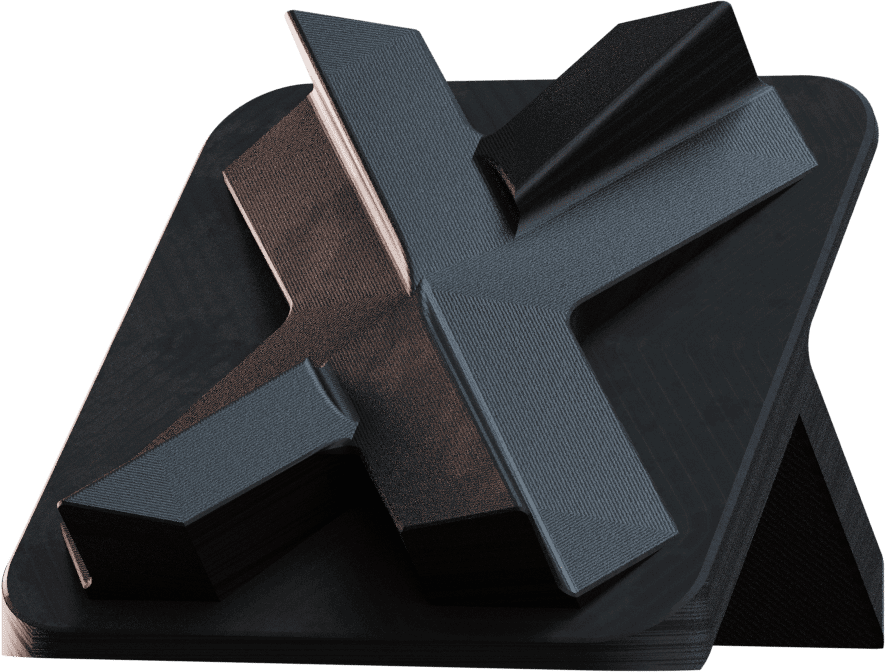

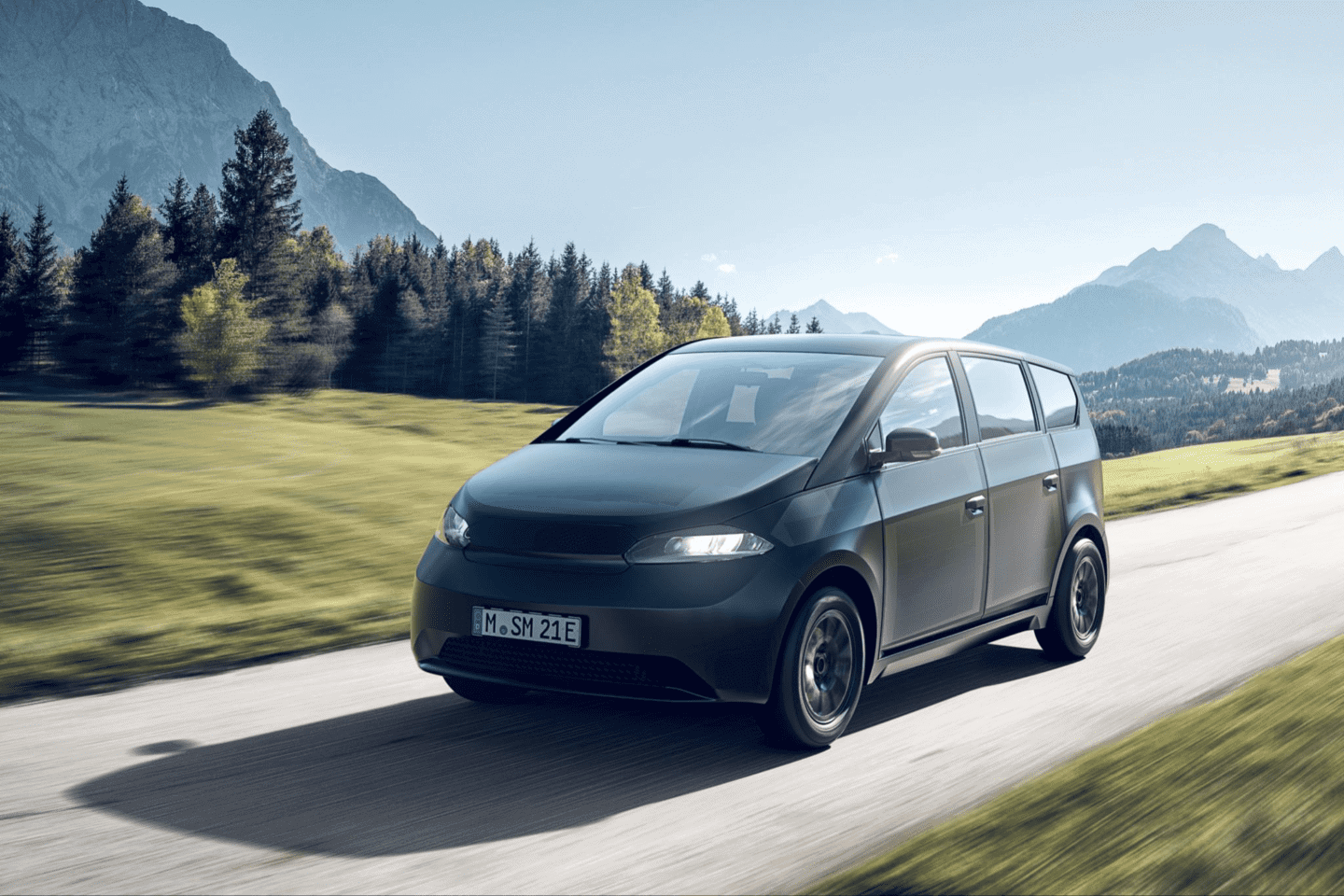

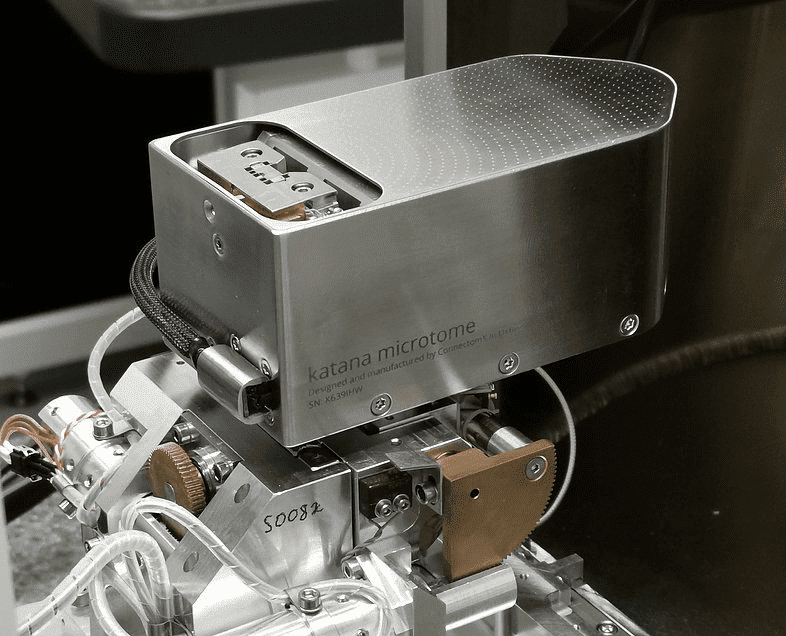

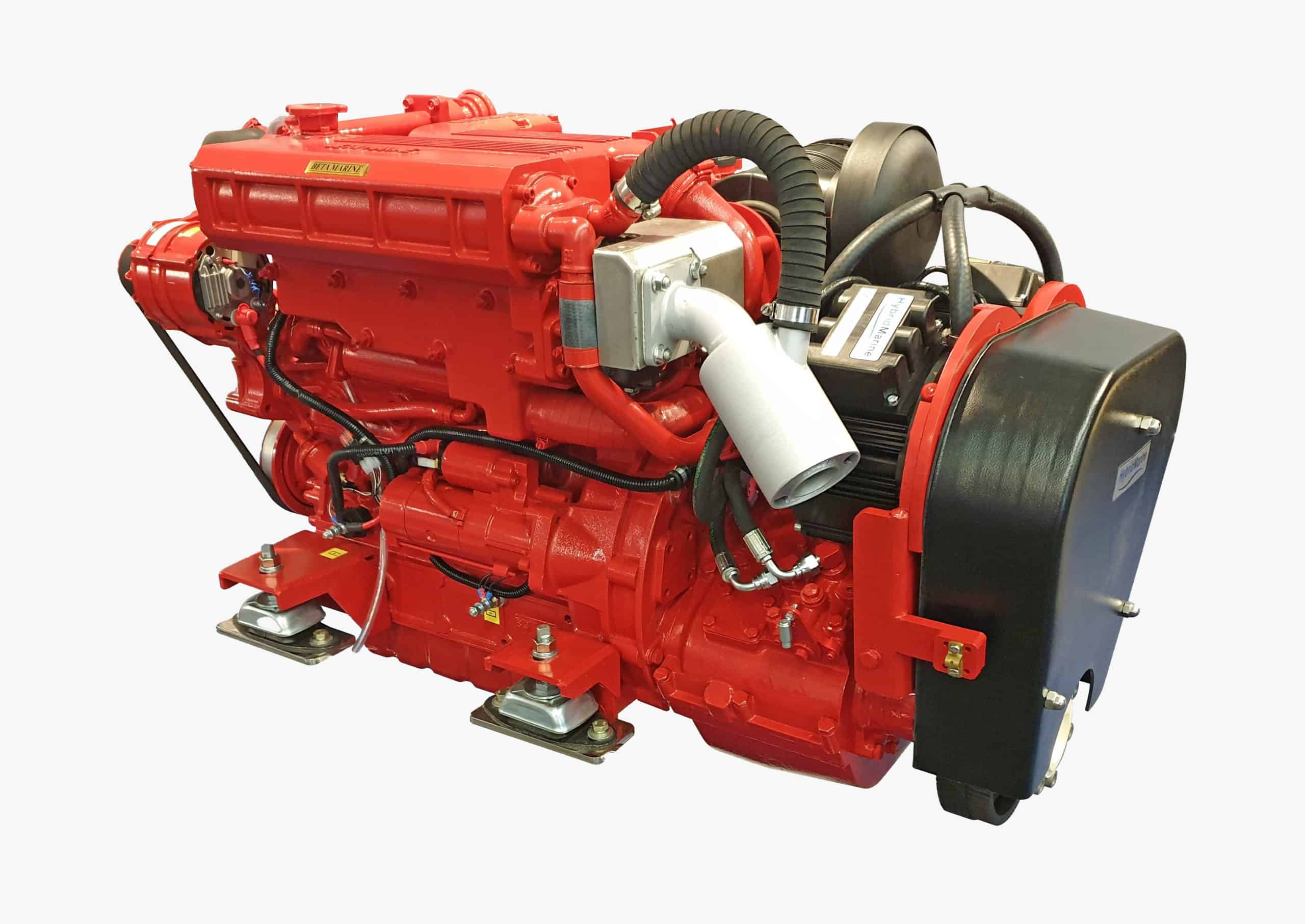

CNC-Bearbeitungsprojekte hergestellt mit Xometry

Übersicht: Was ist CNC-Bearbeitung?

Die Grundlagen der CNC-Bearbeitung

Die CNC-Bearbeitung ist eine subtraktive Fertigungstechnologie, die durch Computersteuerung gesteuert wird. Ein Ingenieur lädt CAD-Modelle hoch und die Maschine erstellt CNC-Teile mit extrem hoher Genauigkeit, indem durch CNC-Zerspanung das Material von Metall- oder Kunststoffblöcken abgetragen wird. Dabei können unterschiedliche Methoden eingesetzt werden: CNC-Fräsen, CNC-Drehen oder CNC-Bohren. Dazu können unterschiedliche Werkzeugmaschinen zum Einsatz kommen, wie z. B. eine 3-Achs- oder 5-Achs-Fräsmaschine. Durch die Fähigkeit, das Werkstück aus verschiedenen Winkeln zu bearbeiten, können 5-Achs-Fräsmaschinen die Bearbeitungszeit reduzieren und die Genauigkeit verbessern.

Erfahren Sie mehr darüber in unserem Handbuch.

Laden Sie einfach Ihre CAD-Dateien hoch und wählen Sie das gewünschte Verfahren sowie das Material und die Oberflächenveredelung aus. Wir produzieren Ihre Teile, wie CNC-Frästeile mit höchster Präzision und Qualität und liefern sie innerhalb kürzester Zeit direkt zu Ihnen. Profitieren Sie von unserem schnellen und einfachen Bestellprozess und unserem umfangreichen Wissen in der CNC-Fertigung. Bestellen Sie jetzt und erleben Sie die Vorteile der CNC-Bearbeitung bei Xometry!

Ressourcen für die CNC-Bearbeitung

Ressourcen zur CNC-Bearbeitung

Jetzt CNC-bearbeitete Teile Bestellen

Alle Uploads sind sicher verschlüsselt und werden vertraulich behandelt.

Europa

Europa  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia