Spritzguss-Fertigung

- Spritzgießen, Insert-Moulding (Umspritzen), Overmoulding (Überspritzen)

- Einzelkavitäten-, Mehrfachkavitäten-, und Familienwerkzeuge

- Kunststoffe, Harze

- Ideal für Serienproduktion von Kunststoffteilen

- Rapid Tooling Produktion in bis zu 2 Wochen

Neues Spritzguss-Angebot anfordern

STEP | STP | SLDPRT | STL | IPT | 3DXML | CATPART | PTC | PRT | SAT | PDF

Sie können auch Ihre technischen Zeichnungen hochladen

Spritzgussdienste

Das Spritzguss Verfahren ist eine kosteneffektive Methode zur Serienfertigung von Kunststoffteilen, das können A-Teile, B-Teile und C-Teile sein. Es garantiert eine konsistente Qualität und ist ideal sowohl für die Herstellung von Klein- als auch Großserien, insbesondere im Bereich des Thermoplast- und Elastomerspritzgusses sowie beim Duroplast Spritzguss. Bei Xometry bieten wir eine breite Palette an steifen Kunststoffen und Harzen an, die verschiedene mechanische und ästhetische Anforderungen erfüllen können.

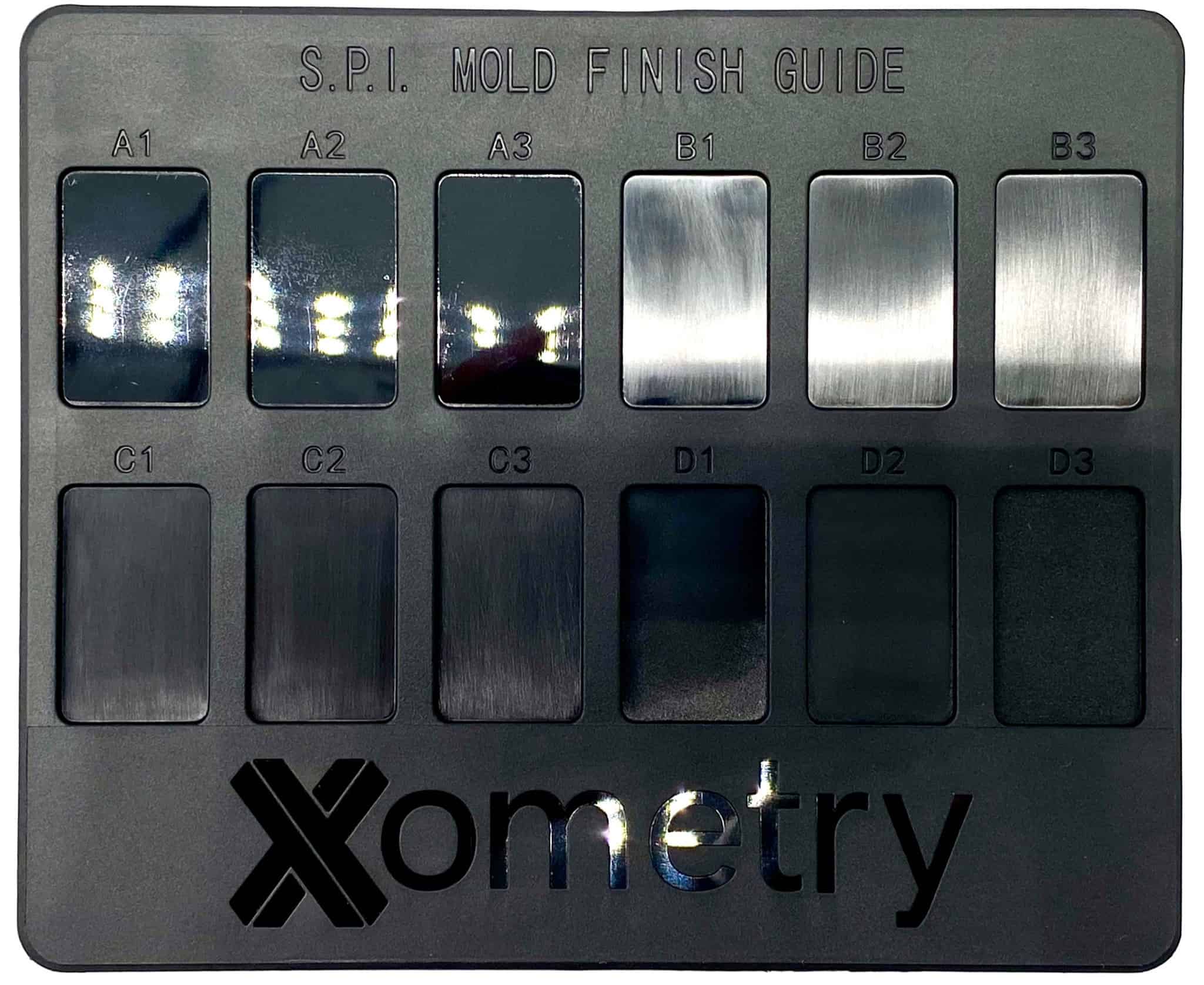

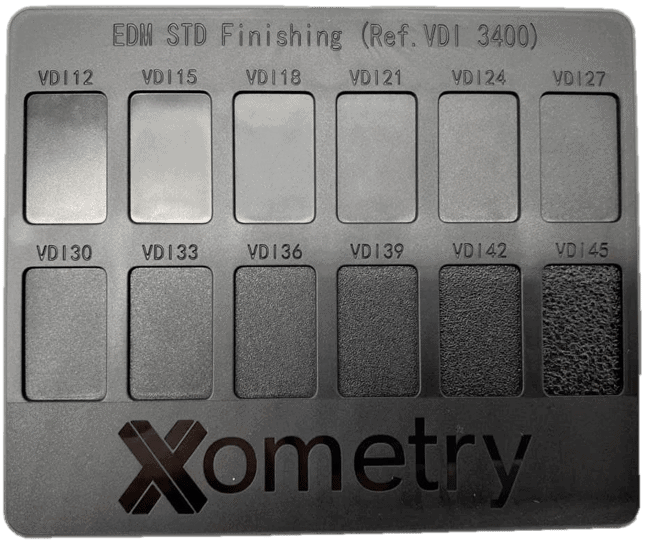

Außerdem bieten wir unseren Kunden die Möglichkeit, Spritzgussformteile oder Kunststoffteile mit speziellen Oberflächenveredelungen, Polierungen oder Oberflächenstrukturen zu versehen. Mit unserem Service bieten wir sowohl eine hochpräzise Werkzeugherstellung als auch Spritzgussfertigung an, wodurch wir uns als ideale Partner für Kunststoff-Spritzguss auszeichnen. Bei Fragen oder benötigter Hilfe zu Ihrem Projekt, kommen Sie gerne per E-Mail oder Telefon mit uns in Kontakt.

Spritzguss Leistungen von Xometry

Fertigungsmöglichkeiten

Spritzguss, Insert-Moulding, Overmoulding

Durchlaufzeit

Ab 10 Werktage

Fertigung von Spritzgießwerkzeugen

Rapid Tooling: Empfohlen für 100-10.000 Teile / Production Tooling: Empfohlen ab 10.000 Teilen

Materialien

Kunststoffe und Harze

Verfügbare Maschinen

Einzelkavitäten-, Mehrfachkavitäten- und Familienwerkzeuge; 50 bis 1.100+ Tonnen Anpresskraft; seitliche Schieber einschließlich manuell eingeführter Kerne

Toleranzen der Spritzgießwerkzeuge

± 0,1 mm aufgrund der Fertigung des Werkzeugs und zusätzlich ± 0,05 mm aufgrund der Schwindung

Wiederholgenauigkeit von Teil zu Teil

±0,1 mm oder weniger

Toleranzen kritischer Merkmale

Engere Toleranzen sind auf Anfrage möglich und können aufgrund der zusätzlichen Fertigungsschritte zu höheren Werkzeugkosten führen. Xometry fräst wichtige Merkmale in stahlsicheren Maßen.

Verfügbare Formtypen

Aus Stahl (Werkzeugstahl, Kohlenstoffstahl) und Aluminium. Die Produktionsqualität reicht von Klasse 105 für Prototypen-Formen bis Klasse 101 für hochpräzise Produktionsformen.

Vorteile des Spritzgießens von Xometry

Kurze Durchlaufzeiten

Wir bieten Ihnen kurze Durchlaufzeiten für Kunststoff-Spritzguss oder für Spritzgießwerkzeuge. Mit unserem Rapid Tooling können wir Ihre Anforderungen auch unter hohem Druck innerhalb von nur 10 Werktagen erfüllen, während unser Production Tooling in bis zu 20 Tagen bereit ist.

Serienproduktion

Unsere Spritzgießverfahren eignen sich ideal für die Serienproduktion ab einer Stückzahl von 100 Teilen.

Präzision

Xometry bietet höchste Präzision mit engen Toleranzen von bis zu ±0,07 mm gemäß ISO 16742, je nach Genauigkeit des Spritzgießwerkzeugs und der Größe der Teile.

Spritzgießwerkzeuge

Unser Angebot an Spritzgießwerkzeugen umfasst Einzelkavitäten-, Mehrfachkavitäten- und Familienwerkzeuge für den Kunststoff-Spritzguss.

Materialauswahl

In unserer riesigen Materialauswahl finden Sie problemlos ein geeignetes Material mit der gewünschten Festigkeit und Oberflächenqualität.

Qualitätskontrolle

Unsere Abteilung für Qualitätssicherung (QS) führt strenge Qualitätskontrollen durch und sorgt für hohe Produktionsstandards.

Xometry Spritzguss-Klassen

| Werkzeugklasse | Zyklen | Produktionsniveau | Grundmaterial | Mindesthärte (BHN) | Beschreibung |

|---|---|---|---|---|---|

| 101 | >1 million | Hoch | Hitzebehandelter Edelstahl | 280 | Kurze Zykluszeiten und sehr hohe Produktionsraten |

| 102 | <1 million | Mittel-Hoch | Hitzebehandelter Werkzeugstahl | 280 | Gut für Teile aus abrasiven Materialien und enge Toleranzen |

| 103 | <50,000 | Mittel | P20 Stahl | 165 | Weitverbreitet für Serien mit niedrigen bis mittleren Stückzahlen |

| 104 | <10,000 | Niedrig | Baustahl, Aluminium oder Legierungen | <165 | Gut für Serien mit begrenzter Stückzahl insbesondere mit nicht abrasiven Materialien |

| 105 | <500 | Sehr niedrig | Weichaluminium, Epoxy, Gusswerkstoff | <165 | Hauptsächlich für die Prototypen-Produktion |

Werkstoffe für den Spritzguss

- ABS

- Acryl

- HDPE

- Industrielle PEEK

- LDPE

- Nylon 6

- Nylon 66 / Nylon 6/6

- PBT

- PC (Polycarbonat)

- PC-ABS Polycarbonat

- PC-PBT

- PEI (Ultem)

- PET

- PLA

- Polyethylen (PE)

- Polypropylen (PP)

- Polystyrol (PS)

- POM / Delrin Acetal

- PPE-PS

- PPS

- PSU

- PVC

- TPE (Elastomer)

- TPV (Gummi)

Spritzgießprojekte mit Xometry hergestellt

Wie die Bestellung von Spritzgussteilen abläuft

1. Anfrage zur Fertigung

Laden Sie Ihre Entwürfe hoch und wählen Sie die Anzahl, das Material und den Farbton. Dadurch wird das Spritzguss Verfahren in Gang gesetzt. Sie können auch spezielle Anforderungen angeben, die bei der Herstellung berücksichtigt werden müssen.

2. Angebot & DFM-Analyse

Innerhalb von 48 Stunden erhalten Sie von uns ein Angebot und eine Design-for-Manufacturability-Analyse (DFM-Analyse) für das Spritzguss Verfahren. Die DFM-Analyse stellt sicher, dass Ihre Teile hergestellt werden können und berücksichtigt dabei auch die Effizienz der Produktion.

3. Fertigung der Spritzgießwerkzeuge

Nachdem das Design der Spritzgießwerkzeuge genehmigt wurde, beginnen wir mit der Fertigung der Formen. Diese sind notwendig, um die Teile herzustellen.

4. Musterteile

Wir stellen Musterteile her, um sicherzustellen, dass sie Ihren Anforderungen entsprechen. Dabei führen wir strenge Qualitätskontrollen durch und senden Ihnen die Muster zur Überprüfung zu.

5. Abschluss der Produktion

Nachdem die Musterteile genehmigt wurden, starten wir mit der Großserienproduktion. Dabei stellen wir sicher, dass Ihre Teile in hoher Qualität und in der gewünschten Anzahl hergestellt werden.

6. Lieferung

Sobald die Produktion abgeschlossen ist, werden Ihre fertigen Bauteile direkt an Sie geliefert. Dies gewährleistet eine schnelle und bequeme Abwicklung.

Tipps zur Kostenreduktion beim Spritzguss

Das Spritzgießen ist ein häufig verwendetes Fertigungsverfahren, bei dem flüssiges Material in eine Form eingespritzt und dann abgekühlt wird, um ein fertiges Teil herzustellen.Wenn Sie die Kosten Ihres Spritzgussprojekts minimieren möchten, müssen Sie die drei wichtigsten Kostentreiber des Verfahrens kennen: Werkzeugkosten, Materialkosten und Produktionskosten.

Die Werkzeugkosten sind konstant, während die Material- und Produktionskosten vom Produktionsvolumen abhängen. Bei kleineren Produktionsserien sind die Werkzeugkosten der größte Kostentreiber, während bei größeren Stückzahlen die Material- und Produktionskosten überwiegen. Hier sind sechs Tipps, um die Kosten beim Spritzgießen zu senken:

- Vermeiden Sie Seitenkerne und andere Mechanismen in der Form, da sie die Werkzeugkosten schnell erhöhen können.

- Vermeiden Sie Hinterschneidungen in Ihrem Design, da sie die Kosten und Komplexität der Form erhöhen.

- Verkleinern Sie Ihr Spritzgussteil, um die Produktionszeit zu verkürzen und die Materialkosten zu senken.

- Passen Sie mehrere Teile in eine Form ein, um die Gesamtproduktionszeit zu verkürzen und die Werkzeugkosten zu senken.

- Vermeiden Sie kleine Details, die zu längeren Bearbeitungs- und Nachbearbeitungszeiten führen und zusätzliche Kosten verursachen können.

- Verwenden Sie einfachere Oberflächen, um die Kosten für die Oberflächenbehandlung zu senken.

Xometry ist Ihr Partner für den Kunststoff-Spritzguss. Wenn Sie diese Tipps beherzigen, können Sie die Kosten Ihres Projekts signifikant senken sowie Powder Injection Molding optimieren und so Ihr Projekt im Rahmen Ihres Budgets halten. Ganz egal, ob es sich dabei um Thermoplast Spritzgießen, Duroplast Spritzgießen oder auch Elastomer Spritzgießen handelt. Wenn Sie an einer Kalkulation interessiert sind oder mehr über uns erfahren möchten, können Sie uns gerne per E-Mail oder Telefon kontaktieren.

Xometry bietet auch diese Leistungen an

Spritzgussteile Online bestellen

Alle Uploads sind sicher verschlüsselt und werden vertraulich behandelt.

Europa

Europa  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia