| Blechdickenbereiche | Schnittbereiche |

|---|---|

|

Aluminium: 1,0-6,0 mm |

Dünne Bleche bis zu 4 mm Dicke: 1000 x 2000 mm, 1250 x 2500 mm, 1500 x 3000 mm |

|

Stahl: 0,8-20 mm |

Dicke Bleche über 4 mm Dicke: 1500 x 3000 mm, 2000 x 3000 mm, 1500 x 6000 mm |

|

Edelstahl: 0,5-16 mm |

|

Blechteile Online bestellen

- Expressfertigung ab 7 Tagen

- Aluminium, Stahl, Edelstahl

- Prototypen- und Serienfertigung

- Zertifizierungen und Prüfberichte

Neues Blechteil-Angebot anfordern

STEP | STP | SLDPRT | STL | IPT | 3DXML | CATPART | PTC | PRT | SAT | DXF

Sie können auch Ihre technischen Zeichnungen hochladen

Blechteile Online bestellen

Bestellen Sie Ihre Blechteile jetzt und lassen Sie sie in bis zu 10 Tagen fertigen

Als führender Online-Fertiger stellt Ihnen Xometry die Möglichkeit zur Verfügung, Blechteile durch Zuschnitts- und Formungsdienste herzustellen. Mithilfe automatisierter Prozesse können wir eine außergewöhnliche Präzision und Qualität für Ihre fertigen Teile garantieren. Des Weiteren bieten wir Ihnen die Option, Ihre Blechteile mit Beschichtungen, Wärmebehandlungen oder anderen Nachbearbeitungen zu behandeln, um Ihre individuellen Bedürfnisse zu erfüllen. Diese können Sie dann ganz unkompliziert über unsere Online-Plattform bestellen.

Unser Ziel ist es, unseren Kunden einen umfassenden Service zu bieten und Ihre Zufriedenheit zu gewährleisten. Wir sind stolz auf unsere Fähigkeit, eine breite Palette von Blechteilen für verschiedene Anwendungsbereiche herstellen zu können. Wir sind uns sicher, dass wir auch für Ihre Anforderungen die passenden Lösungen bereithalten.

Xometry kann auf Wunsch auch Zertifizierungen (Konformitätszertifikat, Rohstoffzertifikat, etc.) und Prüfberichte (CMM, FAIR, Messbericht) erstellen.

Lernen Sie, wie Xometry funktioniert

Testen Sie Xometry jetzt in nur wenigen Schritten

Laden Sie zunächst Ihre CAD-Datei hoch. Sie können mehrere Designs für verschiedene Blechteile online gleichzeitig importieren, um ein einziges Angebot zu erstellen. Innerhalb weniger Minuten wird ein detaillierter Kostenvoranschlag auf Ihrem Bildschirm angezeigt.

Beginnen Sie zunächst mit der Auswahl des gewünschten Herstellungsverfahrens, beispielsweise der Blechbearbeitung. Anschließend können Sie aus einer Vielzahl von Materialien, einschließlich Metallen und Kunststoffen, wählen und eine passende Kombination aus verschiedenen Veredelungen und Zertifizierungen treffen, die Ihren Anforderungen entspricht.

Sobald Sie die gewünschten Optionen ausgewählt haben, bestätigen Sie einfach Ihre Bestellung und zahlen direkt über unsere sichere Zahlungsplattform. Profitieren Sie von unserem Know-how, da Ihr Entwurf von unseren Ingenieuren sorgfältig analysiert wird.

Unser Express-Service stellt sicher, dass Ihre Teile innerhalb kürzester Zeit direkt an die von Ihnen gewählte Lieferadresse gesendet werden. Sie können Ihr Paket jederzeit online in Ihrem persönlichen Xometry-Konto unter „Meine Bestellungen“ verfolgen.

Vorteile der Bestellung von Blechteilen bei Xometry

Schnelle Abwicklung

Durch die Kombination der neuesten Schneid-, Biege- und Stanztechnologien mit automatisierten Technologien bietet Xometry als Online-Fertiger sofortige Angebote für Blechteile in bis zu 10 Tagen. Die automatisierten Prozesse ermöglichen eine schnelle Angebotserstellung und eine zeitnahe Umsetzung der Teile.

Präzision

Xometry bietet verschiedene Toleranzoptionen nach ISO 2768 (Standard, fein) und ISO 286 (Grade 8, 7, 6).

Kundenspezifische Veredelung

Wählen Sie aus einer Vielzahl von Oberflächenbehandlungen für Metall- und Kunststoffteile, die nach präzisen Designspezifikationen gefertigt werden.

Materialauswahl

Entscheiden Sie sich aus einer großen Auswahl an Blechen, die in verschiedenen Stärken, Leitfähigkeiten, Gewichten und Korrosionsbeständigkeiten erhältlich sind. Wir bieten Ihnen eine breite Palette an Materialien, aus denen Sie das passende Blech für Ihr Projekt auswählen können.

Qualitätssicherung

Unsere QA-Abteilung führt eine umfassende Qualitätssicherung durch, um sicherzustellen, dass Ihre Teile perfekt gefertigt werden.

Zertifizierungen und Prüfberichte

Xometry kann Zertifizierungen (Konformitätszertifikate für die Auftragsarten 2.1 und 2.2, Rohstoffzertifikate für Metalle und Kunststoffe, Wärmebehandlungsprotokolle und RoHS-Zertifikate) und Prüfberichte (CMM, First Article Inspection Report – FAIR, Messbericht) zur Verfügung stellen.

Bestellen Sie Ihre Blechteile jetzt und lassen Sie sie in bis zu 10 Tagen fertigen

Zum Sofort-AngebotAlle Uploads sind sicher und vertraulich.

Blech-Materialien

- Aluminium 5052 / 3.3523 / AlMg2.5

- Aluminium 5083 / 3.3547 / Al-Mg4.5Mn

- Aluminium 5754 / 3.3535 / Al-Mg3

- Aluminium 6060 / 3.3206 / Al-MgSi

- Aluminium 6061 / 3.3211 / Al-Mg1SiCu

- Aluminium 6082 / 3.2315 / Al-Si1Mg

- Aluminium 7075 / 3.4365 / Al-Zn6MgCu

- Stahl 1.0117 / S235J2 / S235J2G4, gebeizt und geölt

- Stahl 1.0038 / S235JR

- Stahl 1.0044 / S275JR

- Stahl 1.0117 / S235J2 / S235J2G4

- Stahl 1.0330 / DC01

- Stahl 1.0503 / C45

- Stahl 1.0570 / S355J2G3

- Stahl 1.1191 / XC48H1 / C45E

- Stahl 1.2379 / X153CrMo12 / SKD11, geglüht

- Stahl 1.2510 / 100MnCrW4 / SKS3, geglüht

- Stahl 1.7218 / 25CrMo4

- Stahl 1.7225 / 42CrMo4

- Edelstahl 304 / 1.4301 / X5CrNi18.10

- Edelstahl 316L / 1.4404 / X2CrNiMo17-12-2

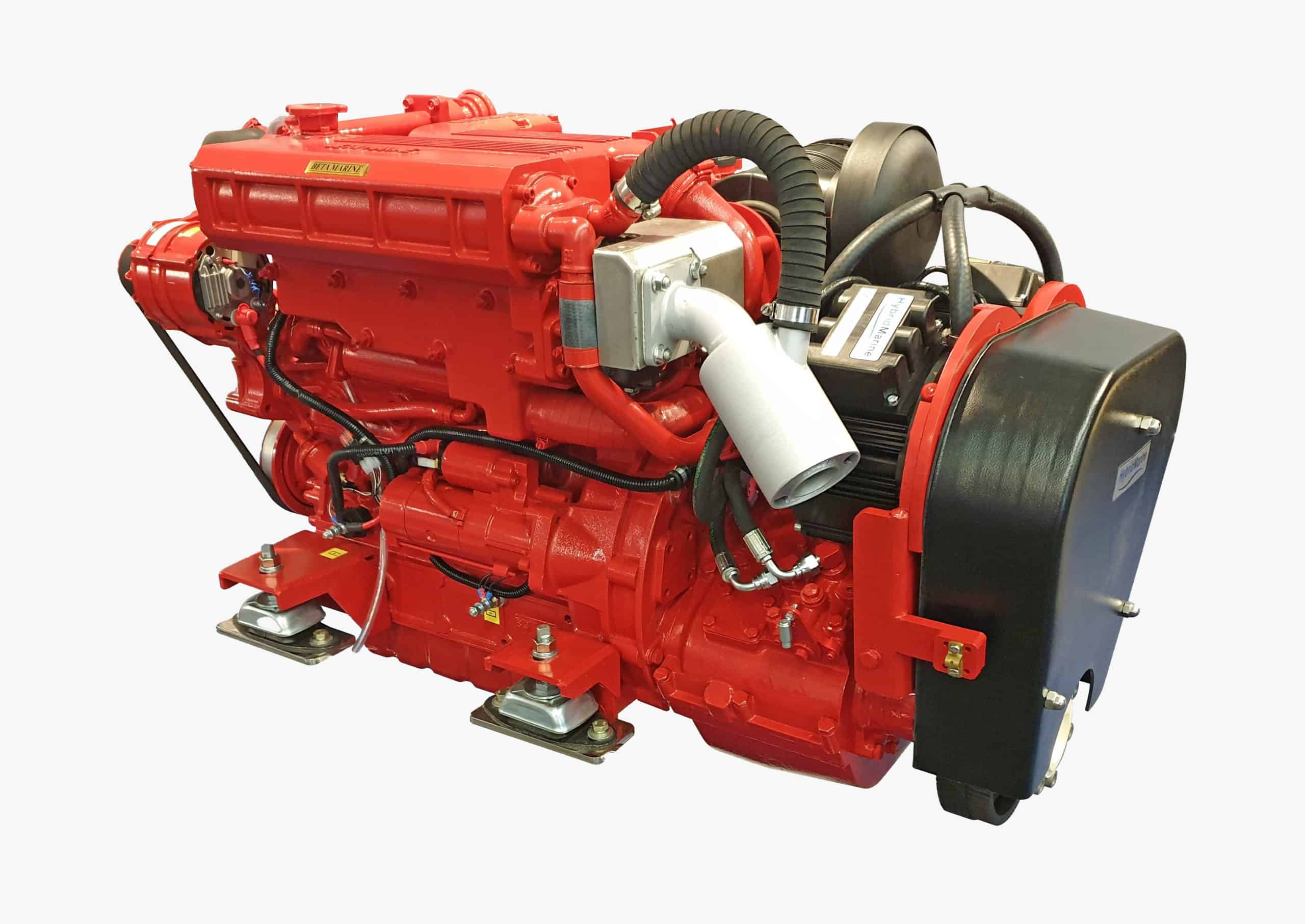

Blechbearbeitungsprojekte hergestellt mit Xometry

Spezifikationen zur Blechfertigung

| Blechdickenbereiche | Schnittbereiche |

|---|---|

|

Aluminium: 1,0-40 mm |

Dünne Bleche bis zu 4 mm Dicke: 1000 x 2000 mm, 1250 x 2500 mm, 1500 x 3000 mm |

|

Stahl: 1,0-40 mm |

Dicke Bleche über 4 mm Dicke: 1500 x 3000 mm, 2000 x 3000 mm, 1500 x 6000 mm |

|

Edelstahl: 1,0-40 mm |

|

| Blechdickenbereiche | Schnittbereiche |

|---|---|

|

Aluminium: 2,0-100 mm |

Dünne Bleche bis zu 4 mm Dicke: 1000 x 2000 mm, 1250 x 2500 mm, 1500 x 3000 mm |

|

Stahl: 2,0-100 mm |

Dicke Bleche über 4 mm Dicke: 1500 x 3000 mm, 2000 x 3000 mm, 1500 x 6000 mm |

|

Edelstahl: 2,0-100 mm |

|

| Blechdickenbereiche | Schnittbereiche |

|---|---|

|

Aluminium: 0,5-12 mm |

Dünne Bleche bis zu 4 mm Dicke: 1000 x 2000 mm, 1250 x 2500 mm, 1500 x 3000 mm |

|

Steel: 0,5-10 mm |

Dicke Bleche über 4 mm Dicke: 1500 x 3000 mm, 2000 x 3000 mm, 1500 x 6000 mm |

|

Stainless Steel: 0,5- 8 mm |

|

Übersicht: Was ist Blechbearbeitung?

Die Grundlagen der Blechbearbeitung

In der Fertigungsindustrie ist die Blechbearbeitung ein bedeutender Prozess, der verschiedene Verfahren wie Schneiden, Stanzen, Biegen, Schweißen, Bohren und vieles mehr umfasst. Dieser Prozess wird genutzt, um flache Bleche, die eine Dicke von 0,15 bis 10 mm haben, in Teile und Strukturen verschiedener Formen zu verarbeiten.

Für die Umwandlung von Blechen in unterschiedliche Formen werden verschiedene Werkzeuge wie Scheren, Stanzmaschinen, Abkantpressen und Laser verwendet. Die Wahl des geeigneten Verfahrens hängt dabei von der Art des Blechs, seiner Dicke und den spezifischen Anforderungen ab.

Ein wichtiger Faktor bei der Blechbearbeitung ist die Materialauswahl. Es gibt verschiedene Metalle, wie beispielsweise Aluminium, Edelstahl und Kupfer, die für unterschiedliche Anwendungen verwendet werden. Die Blechbearbeitung wird beispielsweise zur Herstellung von Gehäusen, Chassis, Halterungen, Stanzteilen, Locken und vielem mehr eingesetzt.

Wenn Sie Ihr Wissen über die Blechbearbeitung vertiefen möchten, sollten Sie unbedingt unseren Blog besuchen. Dort erhalten Sie detaillierte Einblicke in die verschiedenen Verfahren, Materialien und Anwendungen.

Damit Sie direkt starten können, laden Sie einfach Ihre CAD-Dateien hoch und wählen Sie die Blechbearbeitung sowie das Material und die Oberflächenveredelung aus. Wir produzieren Ihre Blechteile mit höchster Präzision und Qualität und liefern sie innerhalb kürzester Zeit direkt zu Ihnen. Profitieren Sie von unserem schnellen und einfachen Bestellprozess und unserem umfangreichen Know-How in der Blechbearbeitung. Bestellen Sie jetzt und erleben Sie die Vorteile unserer Blechteil-Angebote!

Blechteile Online Bestellen

Alle Uploads sind sicher verschlüsselt und werden vertraulich behandelt.

Europa

Europa  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia