SLS 3D-Druck-Service

- Kostenlose Lieferung

- PA 12, PA 11, Flex TPU, Alumide

- Fertigung ab 3 Arbeitstagen

- 3D-Druck-Service für Prototypen- und Serienfertigung

Neues SLS 3D-Druck-Angebot anfordern

STEP | STP | SLDPRT | STL | IPT | 3DXML | CATPART | PTC | PRT | SAT

SLS 3D-Druckteile online bestellen

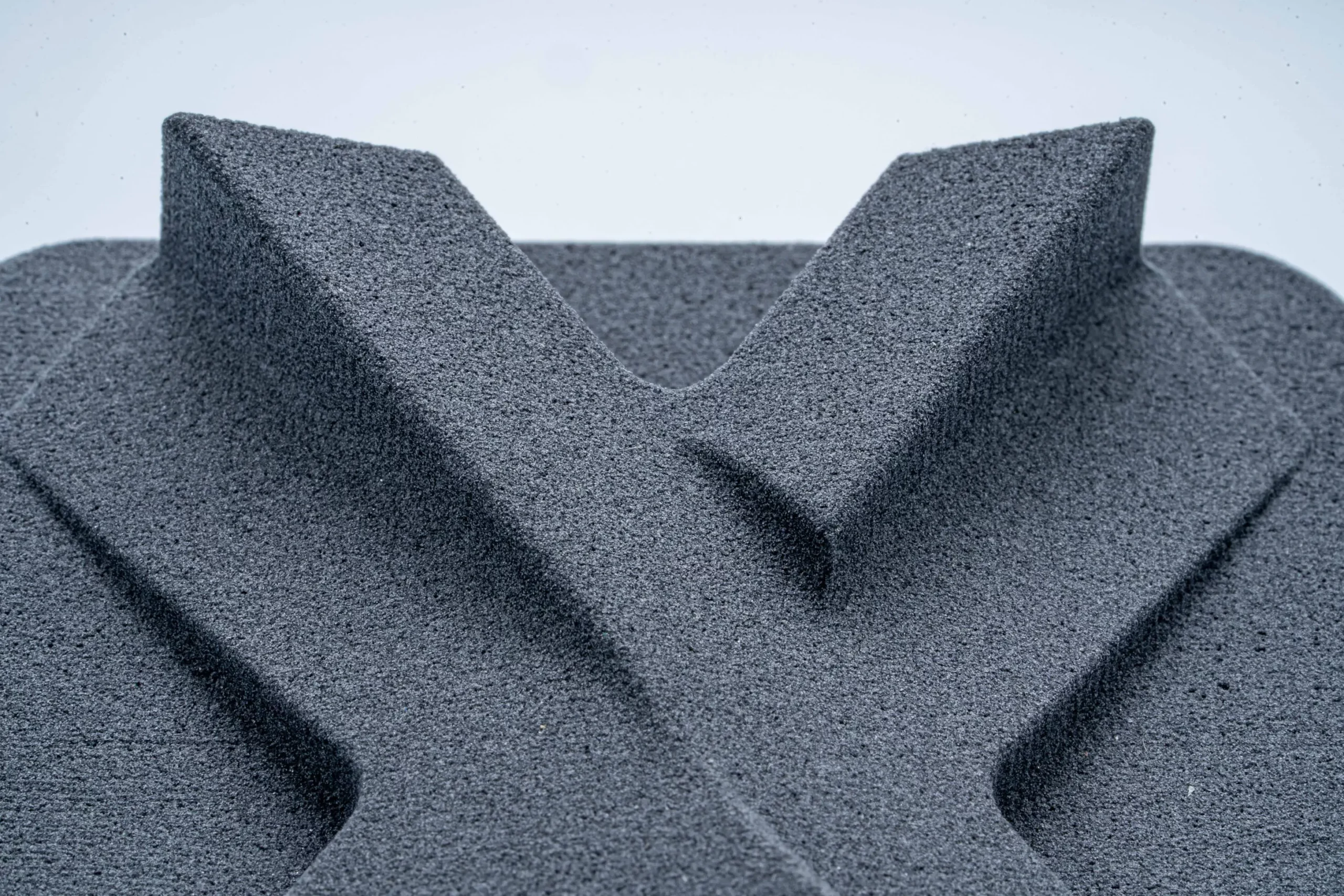

Das selektive Lasersintern (SLS) gilt als eine der weitverbreitetsten und hochmodernen 3D-Druck-Technologien, die es ermöglicht, äußerst präzise und langlebige Bauteile herzustellen. Diese Technologie eröffnet faszinierende Möglichkeiten und ist perfekt geeignet, um sowohl als Endprodukt eingesetzt zu werden als auch in der kleinen bis mittelgroßen Serienproduktion oder für die schnelle Prototypenfertigung. Eine der bemerkenswertesten Eigenschaften des selektiven Lasersinterns ist die hohe Detailgenauigkeit, die es in der Produktion bietet. Die Bauteile werden mit außerordentlicher Präzision hergestellt, was eine erstklassige Qualität und Leistung sicherstellt. Zudem ist die Reproduzierbarkeit der hergestellten Teile absolut zuverlässig, was von großer Bedeutung ist, insbesondere in der Serienproduktion.

Obwohl das SLS-Verfahren eine Spitzenleistung in Bezug auf Detailgenauigkeit und Reproduzierbarkeit erbringt, ist es dazu eine äußerst kosteneffiziente Methode für die industrielle Fertigung von 3D-Druckteilen. Der Grund dafür liegt in der Fähigkeit des SLS, Bauteile in großer Stückzahl ohne Stützelemente herzustellen. Dies reduziert nicht nur den Materialeinsatz, sondern verkürzt auch die Fertigungszeit, was letztendlich zu Kosteneinsparungen führt.

SLS 3D-Druckteile können mit Media Tumbling und Färben nachbearbeitet werden.

Testen Sie Xometry jetzt in nur wenigen Schritten

Laden Sie zunächst Ihre CAD-Datei hoch. Sie können mehrere Designs für verschiedene 3D-Drucke online gleichzeitig importieren, um ein einziges Angebot zu erstellen. Innerhalb weniger Minuten wird ein detaillierter Kostenvoranschlag auf Ihrem Bildschirm angezeigt.

Wählen Sie aus verschiedenen 3D-Druck-Verfahren z. B. Selektives Lasersintern. Anschließend können Sie aus einer Vielzahl von Materialien passende Kombinationen aus verschiedenen Veredelungen und Zertifizierungen wählen, die Ihren Anforderungen entsprechen.

Sobald Sie die gewünschten Optionen ausgewählt haben, bestätigen Sie einfach Ihre Bestellung und zahlen direkt über unsere sichere Zahlungsplattform. Profitieren Sie von unserem Know-how, da Ihr 3D-Design von unseren Ingenieuren sorgfältig analysiert wird.

Unser Express-Service stellt sicher, dass Ihre SLS 3D-Drucke innerhalb kürzester Zeit direkt an die von Ihnen gewählte Lieferadresse gesendet werden. Sie können Ihr Paket jederzeit online in Ihrem persönlichen Xometry-Konto unter „Meine Bestellungen“ verfolgen.

Warum SLS 3D-Druck bei Xometry bestellen?

Riesige Kapazitäten

Dank des größten Fertigungsnetzwerks Europas mit über 2.000 geprüften Partnern können wir sowohl Prototypen als auch Großserien in kürzester Zeit herstellen.

Schnelle Produktion

Ihre 3D-Drucke erreichen Sie in Rekordzeit. Lieferungen sind bereits innerhalb von 3-5 Tagen möglich.

Höchste Qualitätsstandards

Unser internes Team aus QA-Ingenieuren überwacht strenge Qualitätssicherungsverfahren, um Ihnen Teile von herausragender Qualität zu liefern.

Ingenieurprüfung & Statusaktualisierungen

Bevor Ihre Entwürfe in den 3D-Druck gehen, werden sie von Ingenieuren sorgfältig überprüft. Nach Auftragserteilung erhalten Sie regelmäßige Updates zum Status Ihrer Bestellung.

Verfügbare Materialien für den SLS 3D-Druck

- Alumide® / Nylon 12 (PA 12) mit Aluminium verstärkt

- Nylon 11 / PA 11

- Nylon 12 (PA 12) glasfaserverstärkt

- Nylon 12 / PA 12 (SLS, MJF)

- Nylon 12 flamhemmend / PA 2241 FR

- PA 11 lebensmitteltauglich

- PA 12 lebensmitteltauglich

- Polypropylen (PP)

- Flex TPU

SLS-Materialien für spezielle Anwendungen

Lebensmittelechtheit

Lebensmittelechtes PA 11 und PA 12 sind hochgeschätzte, für den Kontakt mit Lebensmitteln geeignete Materialien, die im Zusammenhang mit dem SLS-3D-Druck deutlich an Popularität gewonnen haben. Diese Materialien besitzen eine außergewöhnliche Biokompatibilität und ihre Formel ist speziell dafür entwickelt worden, um die strengen Regeln für Objekte im Kontakt mit Lebensmitteln einzuhalten.

Xometry bietet Ihnen zwei lebensmittelkonforme Materialien für den SLS-Druck:

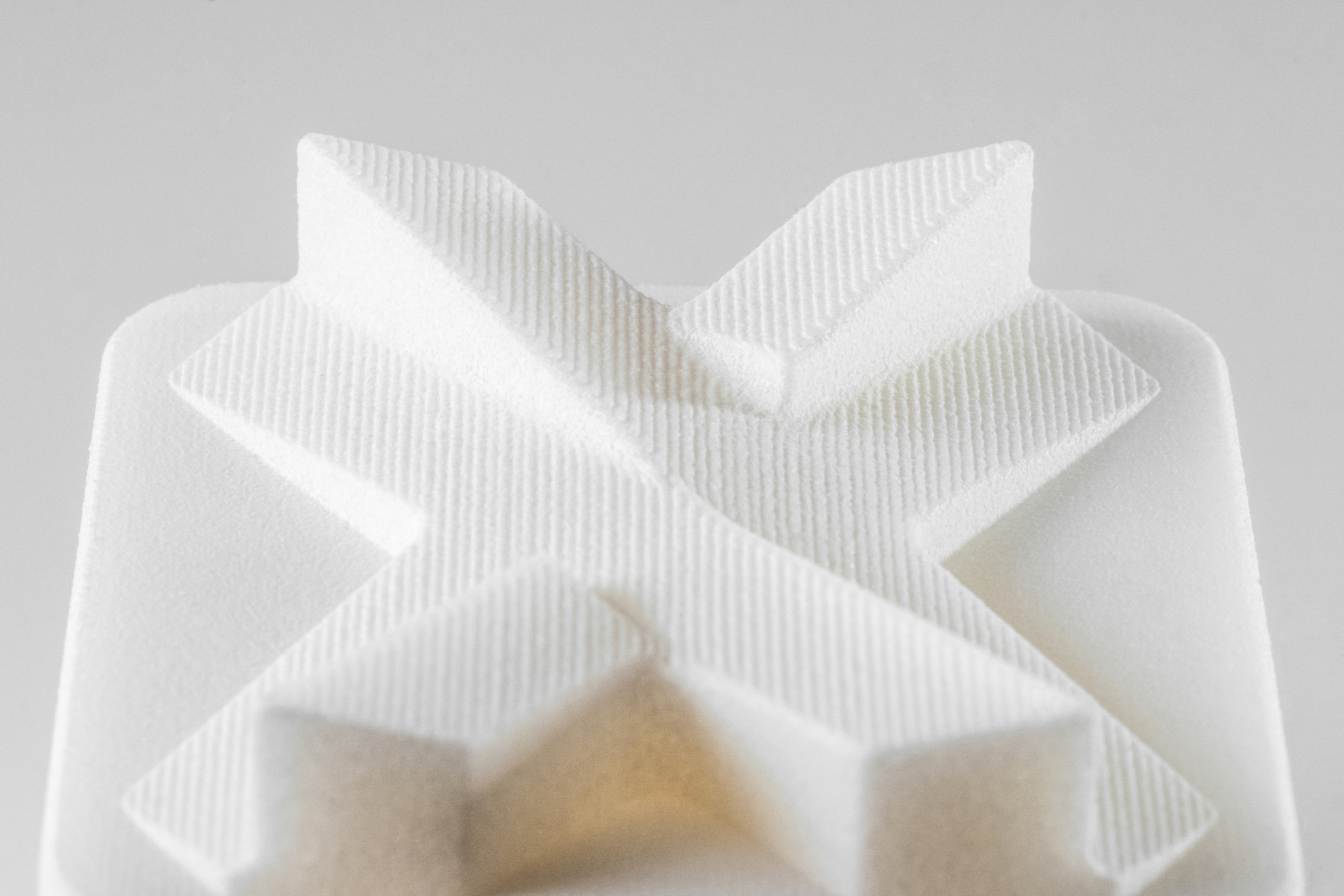

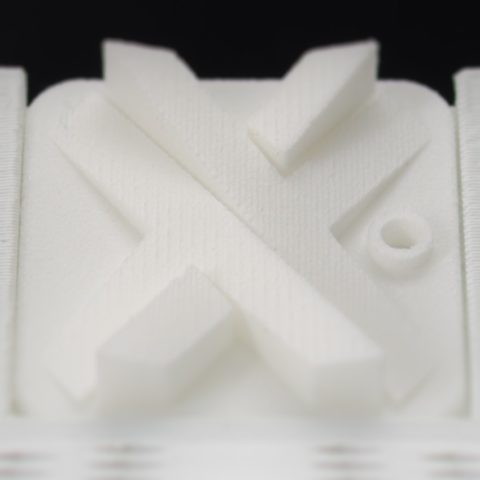

- PA 12 – in weißer Farbe

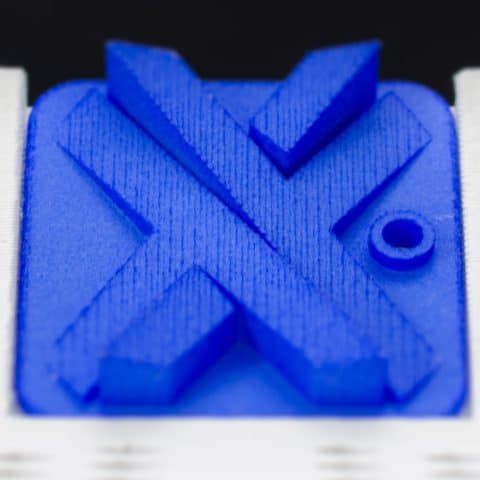

- PA 11 – in blauer Farbe

Flammhemmend

PA 2241 PR ist ein Polyamidpulver, das mit einer konzentrierten flammhemmenden Verbindung durchsetzt ist. Dieses Hochleistungsmaterial erweist sich als höchst vorteilhaft, wenn es darum geht, flammwidrige Bauteile zu produzieren, die dennoch bemerkenswerte mechanische Eigenschaften aufweisen. Dieses Material eignet sich daher auch für Anwendungen in der Luft- und Raumfahrt.

Vor- & Nachteile des SLS 3D-Drucks

| Vorteile | Mankos |

|---|---|

| Freistehendes Design: keine Stützelemente notwendig | Eingeschränkte Material und Farbauswahl |

| Vielseitiges, langlebiges, flexibles und chemikalienbeständiges Material (Nylon) | Oberflächenrauigkeit (lässt sich durch Media Tumbling reduzieren) |

| Skalierbar in Serienproduktion | Anfällig für Verkrümmungen bei großen Merkmalen |

| Schnell: Xometry kann innerhalb von nur 3 Tagen liefern | |

| Günstig |

SLS Fertigungsspezifikationen & -kapazitäten

| SLS | HP MJF | SLA | FDM | Carbon DLS | DMLS | Polyjet | |

|---|---|---|---|---|---|---|---|

|

Durchlaufzeit |

3 Tage |

3 Tage |

7 Tage |

8 Tage |

5 Tage |

5 Tage |

7 Tage |

|

Fertigungsvolumen |

bis zu 340 x 340 x 605 mm, wir empfehlen normalerweise ein maximales Maß von 320 x 320 x 580 mm |

bis zu 380 x 284 x 380 mm, normalerweise empfohlene maximale Maße von 356 x 280 x 356 mm |

• 145 × 145 × 185 mm (Standard) |

• 350 x 350 x 350 mm (Standard) |

bis zu 119 x 189 x 300 mm. Empfohlene Größe: Innerhalb von 100 x 100 x 150 mm |

400 x 400 x 400 mm |

bis zu 490 mm x 391 mm x 200 mm |

|

Schichtdicke |

~0,1 mm und für wasserdichte Teile 1,5 mm, wenn die Wandstärke größer ist |

~0,08 mm |

min. 0,02 |

~0,05-0,3 mm |

~0,1 mm |

0,02 – 0,08 mm je nach Material |

0,04 mm |

|

Mindestgröße der Merkmale |

0,5 mm |

0,5 mm |

0,2 mm |

bis zu 0,2 mm |

0,5 mm |

0,5 mm für kosmetische Merkmale, 1.5 mm für Strukturmerkmale |

1,2 mm oder größer für starr. 2 mm oder größer für gummiartig |

|

Toleranz |

±0,3% (± 0,3 mm) |

±0,3% (± 0,2 mm) |

• ±0.5% (±0.2 mm) (Standard) |

±0.5% (±0.5 mm) (Standard & Industrielle) |

±0,1% (±0,1 mm). Beim ersten Druck eines neuen Designs können die Toleranzen jedoch nicht gewährleistet werden |

±0,2% (±0,1 – 0,2 mm) |

±0,1 mm für die ersten Dutzend mm ist typisch, plus ±0,05 mm für jeden weiteren mm |

|

Beschreibung |

Eine der beliebtesten und kostengünstigsten Verfahren für den industriellen 3D-Druck |

Ein Prozess, der hochpräzise und langlebige Teile bei hohen Geschwindigkeiten produziert |

Ein Verfahren, das extrem genaue und hochauflösende Teile produziert |

Weithin bekannt für eine große Materialauswahl, Genauigkeit und die Möglichkeit, große Teile zu drucken |

Ein bahnbrechendes Verfahren, das digitale Lichtprojektion und programmierbare Flüssigharze verwendet |

Metall-3D-Druckverfahren. Selektives Verschmelzen eines feinen Metallpulvers in Aluminium oder Edelstahl |

Polyjet ist eine starre Photopolymer-3D-Drucktechnologie, die hochdetaillierte Modelle produziert |

|

Unterstützungsstrukturen |

Nein |

Nein |

Ja, für überhängende Merkmale |

Ja, für überhängende Merkmale |

Ja, für überhängende Merkmale |

Ja, für überhängende Merkmale |

Ja, für überhängende Merkmale |

Xometry bietet auch diese Leistungen an

3D-Druckteile Online Bestellen

Alle Uploads sind sicher verschlüsselt und werden vertraulich behandelt.

Europa

Europa  United Kingdom

United Kingdom  Türkiye

Türkiye  USA & Canada

USA & Canada  Asia

Asia